Mini Cranes, Mobile Portable Lifting Cranes

Our solution to your portable crane rigging needs is a mini floor crane system which can be operated by one or two workers on the jobsite. Electric hoists, chainfalls and make-shift rigging devices, pull-lifts, chain hoist, roust a bout and lifting mechanisms, construction cranes and lifting machinery can be dangerous, leading to workplace accidents and employee injuries. Our portable crane device prevents medical injuries and increases jobsite safety while workers are performing heavy or awkward lifts and rigging or moving heavy objects around the job or shop.

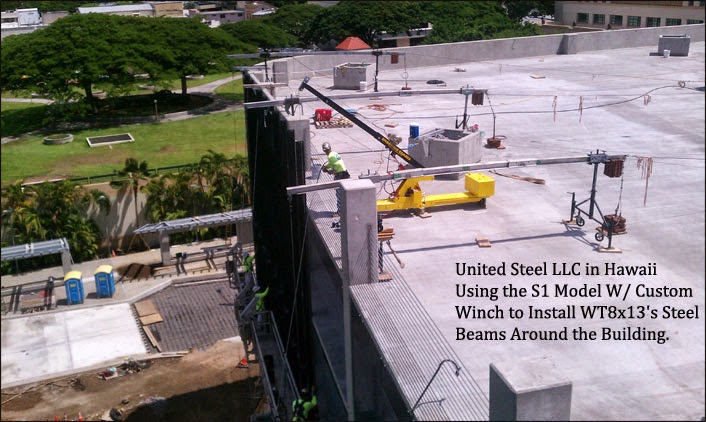

This full powered floor crane for sale provides a lifting solution for removing and replacing differentials, transmissions, alternators, fuel tanks and engine components from truck and transit coaches, infrastructure repair, utility servicing, precast concrete installation. Highly maneuverable alternative, and advanced flexibility in materials handling equipment. Our lift products eliminate back-breaking manual activities, standard door openings and elevators, easily navigate narrow aisles, and are perfect for fork lift restricted use areas. Smart-Rig® Crane equipment is also available as a purpose-built, custom engineered solution for specialized applications and requirements, including chemical industries, food processing applications, and clean room rated equipment requirements.

We manufacture and distribute quality counter-balanced floor cranes and rigging device mechanisms for a variety of industries including heating and air conditioning, general construction, steel erection, pipe fitters, industrial construction, manufacturing, refridgeration, glass lifting and window installation, sign companies, mechanical engineering, robotics, helicopter maintenance for Ejection Seat, Canopy Windshield, Vertical Stabilizer, Ammunition Drum, Horizontal Stabilizer, Cannon Gun Assembly chemical, home builders, aerospace, aviation, aircraft, recycling, log building, tree removal, curtain walling glass installation, moving heavy loads, setting statues/masonry, road work, uranium, forest, environmental, solar installation, transport/moving, architectural glass installation, glass column panels, maintenance, petrochemical, government work, maintenance departments, oil refineries, grain distillers, airplane manufacturing, MAAC, fabrication, ship building, plants and facilities, mechanical, plumbing, ac, masonry, cruise ships, yards, ports and hundreds of industries that require energy saving rigging on-site and multi-purpose below the hook lifting devices for any jobsite.